Table of Contents

In today’s world OEMS are in a competitive market where they are forced to deliver high quality products fast and at lower cost. And PCBs play an important role in that.

In terms of electronics a PCB is a rigid structure where the electronics components are mounted on to it to connect the electronics components to form a circuit. They are the main part of a of an electronics device and efficient production of PCB is crucial for OEM’s.

Hence OEM’s need PCBs. Here is where Electronics manufacturing services comes to play. Having a in house PCB production can be complex. It has high cost of investment, expertise and man power, scaling problems, inventory management, environmental regulations and quality control.

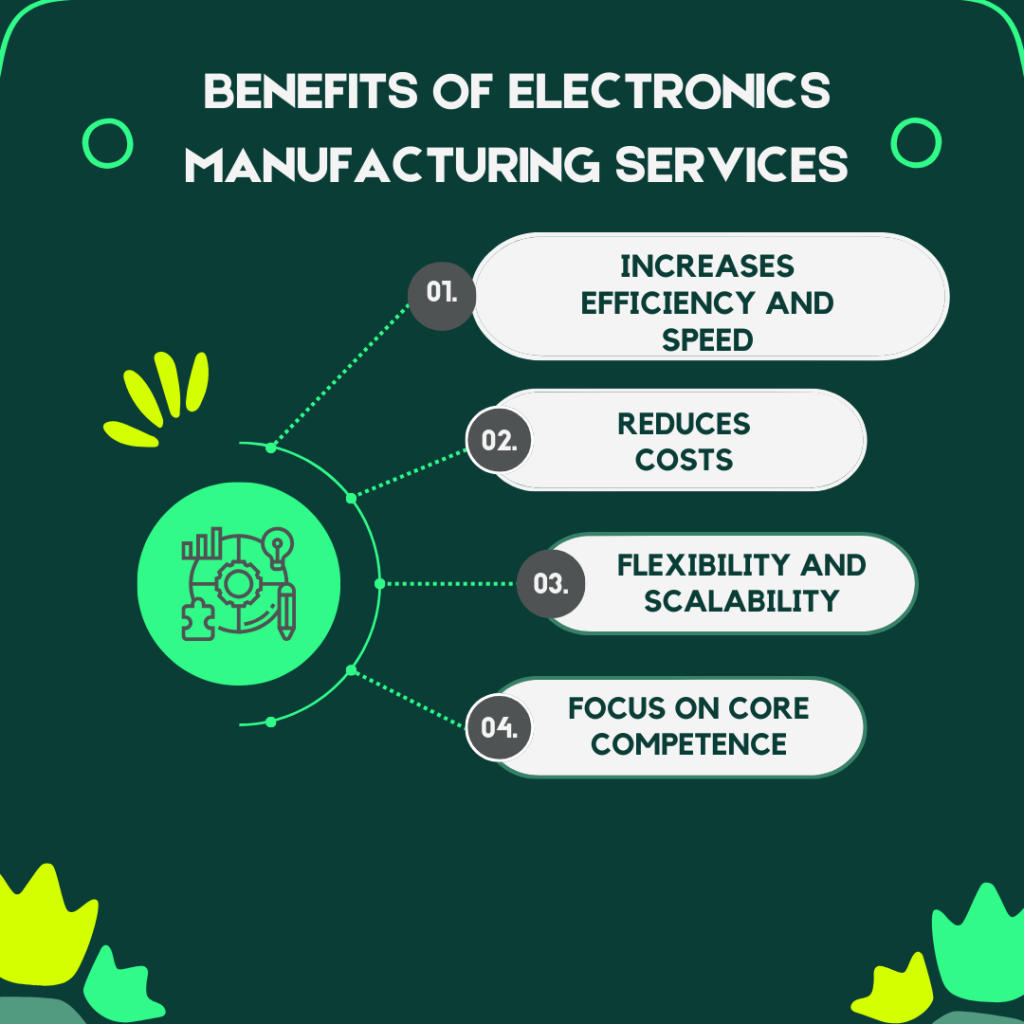

What are the benefits of partnering with electronics manufacturing services?

Since there are lot of cons related to traditional in-house manufacturing many OEM’s partner with EMS companies for more streamlined production. They get benefits like.

Increases efficiency and speed:

EMS provider has high speed and advanced machinery and also, they have experience in different industries and experienced staffs. This results in quick turnaround time in manufacturing which is an essential criterion for an OEM.

For efficiency and speed, they hire electronic manufacturing services as they meet and over exceeds the OEM’s Expectation.

Reduces costs

An EMS provider reduces the complexity in choosing quality materials for your PCB and knows supplier who are reliable. Since they invest in advanced technologies you will get quality services. And also, they follow strict quality control this includes visual inspections and other testing techniques. By adhering to industry standards, they provide Reliability and enhanced quality

This huge cost can be avoided by hiring an Electronics manufacturing Services.

Flexibility and scalability

One of the main advantages that an EMS provider that all OEM’s look for is scalability. It Is no wonder that how the demand in market changes. OEM’s can Request Ems providers to scale up and low in production based on their specific needs. This will help a OEM in lot ways meeting customer satisfaction and speed.

Focus on core competence

Majority of the work is done by EMS the OEMs are free to focus on their core competence like product design, marketing and sales. This allows OEMs to have a stress-free streamlined production.

By partnering with an EMS you can gain competitive advantage over you competitors and have a hassle free production. An Ems can help you reduce cost, increase efficiency and speed, improved quality and flexible scaling.

This is Why Many OEMs Rely on EMS for electronics manufacturing services.

Ready to stream line your Electronics production?

Tecno Systems is a leading provider of EMS solutions with more than 34 years of experience, including expert PCB manufacturing. We offer a wide range of EMS services, industry-leading quality standards, and a commitment to open communication. Contact us today to discuss your specific PCB needs and learn how we can help you achieve your production goals.