Let’s say your mobile phone it is made up of different components like display, motherboard, camera and other components, all these components are combined together to form a mobile phone or smart phone. Box build assembly is nothing but assembling individual electronic components and assembling them into a complete, working product. We can also call this as system integration as well.

In electronics manufacturing industry there are various steps involved in manufacturing any electronic product. It starts from design and prototyping to final product assembly and testing. Box build assembly is a part of electronics manufacturing process.

These services are often outsourced by many OEM’s and Brands based on their requirements. Out sourcing an Electronics manufacturer has its own advantages like cost reduction, proper project management and Efficiency.

Box build assembly includes mechanical and electrical assembly. This requires skills in project management, supply chain, quality control, mechanical integration and testing. If you are an OEM requiring BOX build assembly services you will save a lot of time and money by outsourcing and electronics manufacturer.

Table of Contents

Example of Box build assembly

Box build assembly is a manufacturing process that involves assembling multiple components into a finished product within a case or enclosure. A common example is the assembly of a gaming console. This process typically includes installing the motherboard, CPU, GPU, memory, storage, power supply, cooling system, cables, and controllers into the console’s enclosure. The components are connected together and tested to ensure proper functionality before the final product is shipped. Box build assembly can be customized to meet specific requirements and is often used in a variety of industries, including electronics, consumer goods, and industrial equipment.

Different process involved in Box build assembly.

Box build assembly process is one of the important steps in electronics manufacturing which needs high skill and effort. This process includes strict quality control and inspection to mitigate the defects and faulty products. The various process involves in assembly are:

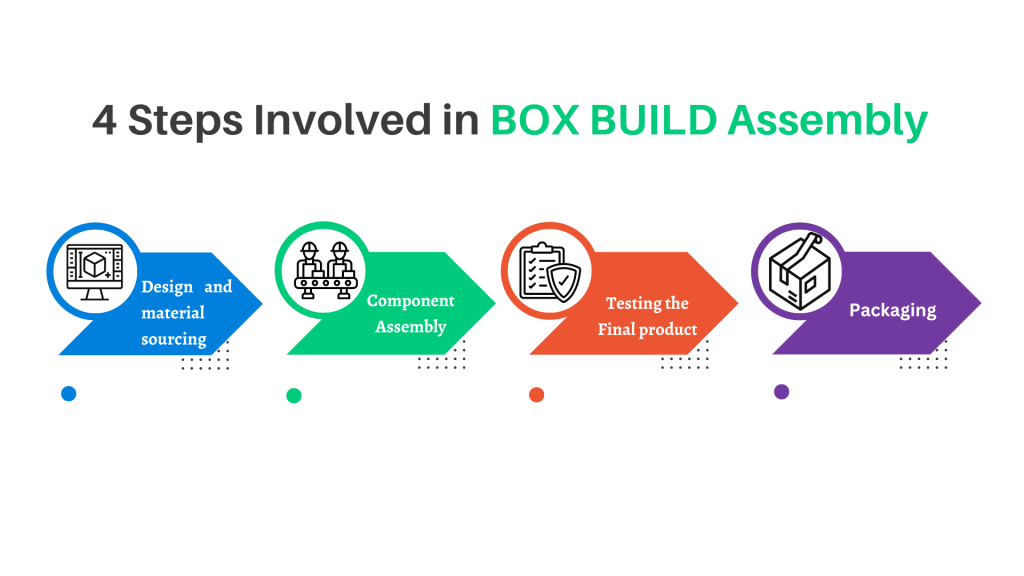

Design and material sourcing

Design is something that’s decided by the person who is availing box build assembly services. They are designed by the designing team who owns the rights to sell the product. In our case they are OEM’s and brands. As per design various materials are sourced like enclosures, screws, cables, connectors and other necessary components. This process is done efficiently by EMS companies because they will have a huge number of contacts and suppliers.

Component Assembly

Here the components like power supply, small modules and other components are assembled together. This is also called sub assembly. This may include integration of mechanical parts if there is any. In this process the components are placed inside the enclosure and the enclosure will me modified if its required. With brackets and screws the PCBs and other components will be placed inside the enclosure. Without compromising its structural integrity and safety. Here the PCB will be mounted inside and connected to various other components like power supply through cable and connectors as required.

Testing the Final product

This is one of the important steps as mentioned earlier Testing and inspection is very important. The inspection and testing in PCB leave would have been done earlier. But after assembly there is a lot of possibilities of defects. Like damaged wires or malfunctioning mechanical parts or other defects. This where the assembled product will be tested and make sure the product is good to serve its purpose.

This ensures the OEM companies not to lag behind scheduled and tight deadline and makes it easy for the product to reach its market on time.

Packaging

The assemble product is ready to be shipped as it is destined to. These final products will be packed safely to avoid getting destroyed or damaged.

Advantages of Box Build assembly

- Cost effectiveness: By box build assembly OEMs and brands can save a huge amount of money. Setting up and Box build assembly line in house requires a significant amount of investment in Technology and labour. But by outsourcing it with an Electronics manufacturing services they can reduce the upfront cost and use the capital in product development or any other process.

- Expertise and specialization: When it comes to expertise and specialization the electronics manufacturers have a huge advantage. They will have skilled work force with experience in handling different and complex projects in different industries. They will make sure your product is assembled and integrated adhering to the industry standards. Hiring a skilled workforce also consumes a lot of capital but it can be reduced by hiring an electronics manufacturing services.

- Focus on core competence: The greatest advantage of outsourcing an electronics manufacturing services is this. You won’t have to worry about project management, quality control, Testing and other headaches related to production, everything will be maintained by dedicated project managers. So that you can focus on more important aspects like customer services and marketing.

- Scalability: EMS partners offer exceptional scalability, effortlessly accommodating both small-scale and large-scale production runs. This flexibility ensures that our production capacity aligns seamlessly with fluctuating market demand, eliminating the need for frequent adjustments to our internal operations

- Supply chain and inventory management: By consolidating your component inventory to a single item through outsourced box build assembly, you can significantly reduce costs. Electronics manufacturing partner leverages economies of scale to negotiate favorable pricing for individual components, sub-assemblies, and logistics, resulting in substantial savings for your organization.

- Quality assurance: An electronics product is prone to defects. But with high quality control and rigorous action manufacturer will be able to mitigate the all the defects. With proper quality control you can save more of the money and time by strict quality control measures.

Should you consider BOX build assembly Services?

The short answer would be yes, because it provides you with greater advantage. There are cons associated with outsourcing box build. This could be lack of communication, capabilities, lack of industrial expertise and delayed in delivery time. But we at Tecno systems India provide world class final product assembly or box build assembly services mitigation all the cons. We provide transparency through out the entire production process and prioritize communication in each and every stages. Our electronics manufacturing plant is capable of provide flexible and scalable assembly units. We prioritize on time delivery keeping the demand for your product in mind.

We are proficient in many industries our experience in EMS industry is more than 34+ years and we have come across challenging and complex projects in various industry.

Looking for a reliable Box build assembly services partner in India?

We are one of the best electronics manufacturing services companies located in Bangalore with high quality PCB assembly facility and Box build services. Our team of experts is here to help you with quality production services.

Contact us today for a Free consultation.