Have you ever wondered how the daily electronics gadgets we use is manufactured or where does it come from? The answer is an EMS (electronic manufacturing services) company.

There is an industry called electronics manufacturing industry that works as a subcontractor for original equipment manufacturers and bug brands. This industry is responsible for manufacturing your daily electronics gadgets and other electronics you use and see in daily life.

EMS industry acts as the back bone for the many industries that is depending upon electronics. The consumer electronics is one of the industries that is heavily depending on the electronics manufacturing services industry. In modern world there is huge demand for electronics in every industry. Industries like defense, automobile, consumer electronics, telecom, aviation and others depend on electronics manufacturing services industry.

The Role of EMS industry in Modern Manufacturing

The major role of EMS industry in modern manufacturing is that they take care of all the aspect of manufacturing electronics product from initial stage to the final product delivery. They play a major role in economy by bring high-quality products to market more quickly and efficiently. Which makes it affordable for consumers.

The EMS industry offer many benefits to the original equipment manufacturers and big brands. The electronics manufacturing industry is an attractive option than having an in-house manufacturing unit.

Some companies even shift to outsourcing electronics manufacturing services from in house manufacturing. This is a new trend that seen now not only in Electronics manufacturing industry also in others.

Benefits of EMS industry

The EMS industry is growing in a fast phase as per fortune business insights the industry is set to grow exhibiting 7.4 CAGR from USD 573.75 billion in 2024 to USD 1017.85 billion by 2031.

As said earlier many companies depend on Electronics manufacturers for manufacturing their electronics , due to market sentiments, government policies and geographic challenges international brands are looking for EMS to partner with.

The major benefits of EMS industry are:

- Outsourcing and Efficiency: electronics manufacturing services providers offer flexible and reliable outsourcing for companies that allow them to reduce costs and improve efficiency by focusing on their core business activities. Cost cutting is one of the major advantages of outsourcing electronics manufacturing. This helps companies and OEMs to keep a competitive pricing.

- Scalability and Flexibility: EMS companies have the ability to rapidly scale their operations to meet fluctuating demand, ensuring that businesses can respond quickly to market changes. Time to market is one of the important factors with flexibility and scalability EMS providers help companies to meet the market demands and ensure customer satisfaction and serving on time.

- Access to Expertise: EMS providers possess specialized knowledge and skills in various industries and various areas of electronics manufacturing, including design, engineering, and quality control. This expertise can be invaluable for companies that lack internal resources or capabilities. EMS providers with many years of experience is a good thing to look for before partnering with them.

When outsourcing a right EMS partner companies won’t have to worry about the complex process in manufacturing. This help them to focus on what is important such as core parts of the business.

Services offered by EMS industry to other industry in terms of manufacturing

EMS providers give a lot of services for OEMs and Brands they are:

- Design and Engineering: EMS industries provide design support to OEMs and brands. They design the prototype from the design submitted by them or from the concept. The prototype will be designed further based on the testing done, there could be any scope of improvement in the initial design. This will then be tested and the proceeded for bulk manufacturing.

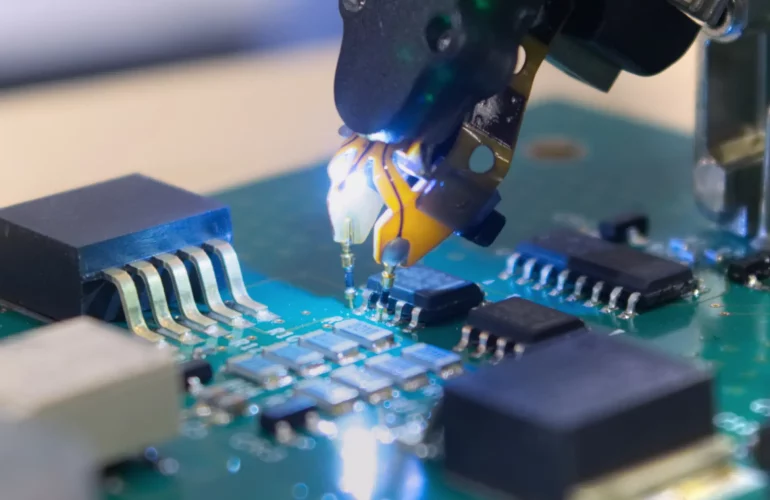

- Manufacturing and Assembly: The technology used to manufacturer electronics is evolving decade by decade. So, there is a constant need to upgrade and stay updated with the market. The EMS companies invest in high end SMT lines and other technologies and provides best manufacturing and assembly services efficiently.

- Testing and Quality Control: EMS companies make sure they follow all quality standards as required. So that you don’t have to worry about certifications and complex back-office process involved in it. They also take care of testing and inspection of your products before they reach your customer. This helps to reduce defects and cost that may lead to mass repair or rework and customer dissatisfaction.

- Supply Chain Management: EMS companies provide services like sourcing of electronic components to packing a delivery to required destinations as your needs. They have efficient and reliable suppliers; this helps continuous supply of components on right time with out disturbing the supply chain.

The impact of EMS industry in manufacturing.

The impact of EMS industry is more evident that it is enhancing manufacturing processes, improving efficiency, and enabling the delivery of higher-quality products under affordable price.

We can see impact of EMS industry is something that we see in a example. Have you seen how much brands you can find when it comes to truly wireless earbuds. Each and every brand is unique and different. All those brands won’t have a dedicated manufacturing unit they will be depending on the EMS companies. This helps them to reduce cost give a competitive price produce high quality products and helps on focusing on their core business.

If you are looking for to partner with an electronics manufacturing service company and wondering how to start get a consultation. We at tecno systems have more than 35+ years of experience in EMS industry and help your product reach your consumer on time assuring quality and precession.

Speak to us, Get a Free consultation

Contact us today to discuss your project and learn how we can help you streamline your operations, improve efficiency, and drive business growth.