We live in a word where electronics have become an integral part of our daily life. We are driven by technology and our life style depend on it depends on it from smart phones to washing machine we depend on electronics. Each and all electronics have an important component, that is PCB also known as printed circuit board.

A PCB is nothing but a thin green board where various electronics components are connected together on to it to form an electrical circuit. A PCB serves as a backbone for electrical connections. It acts as a structural platform where various electrical components like resistors, capacitor, ICs are placed.

Understanding the Basics of PCB Assembly

Printed circuit board assembly also known as PCBA in short is a process involved in manufacturing electronics. PCB assembly means assembling of electronics components on a bare Printed circuit board as per design to form an electronics circuit. The electronics are assembled based on the components most of the electronics manufacturers use surface mount technology (SMT) and Through hole technology (THT).

The assembly process begins with designing the layout of the PCB. This is where the PCB design engineers come up with a functional PCB layout a specialized software is being used to create this PCB layout and ensures every component fits and functions perfectly as intended.

This step is crucial as it determines the positioning and orientation of components on the board.

Once designing is complete the next process is to manufacturer bare PCBs through etching and layering techniques. This is where the oath ways for the electrical components are made to for an electrical circuit.

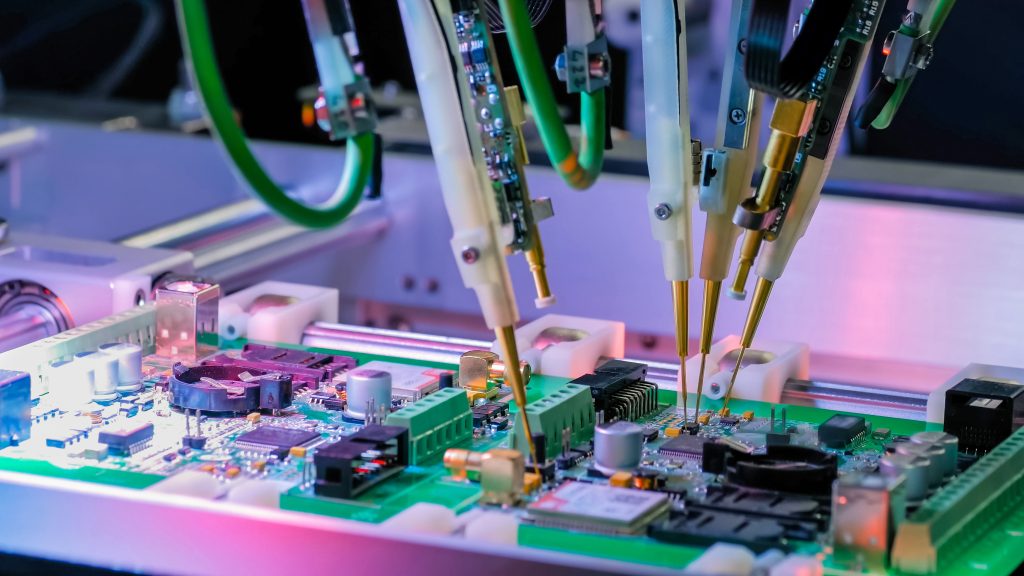

After making bare PCB boards now its time to assemble the components on to the board. components like resistors, capacitors, and integrated circuits are assembled as per the design.

This is where precision matters most; even tiny misalignment can lead to malfunctioning devices.

Most of the commonly used assembly techniques are surface mount technology (SMT)and Through hole technology (THT)

Key PCB Assembly Techniques

There are various techniques to assemble electronic components on to a PCB These are chosen based up on the design and the types of components that are being used used.

One popular method is through-hole technology, where components are inserted into holes on a PCB and soldered in place. This technique offers strong mechanical connections. The components that are used to assemble using Through hole technology (THT) are wired components like resistors, capacitors, diodes, transistors, and integrated circuits (ICs) These components are larger when compared to components used in surface mount technology (SMT).

Another widely used approach is surface mount technology (SMT). Surface mount technology allows components to be mounted directly onto the surface of the PCB, saving space and reducing manufacturing costs. It’s particularly beneficial for compact and high-density applications.

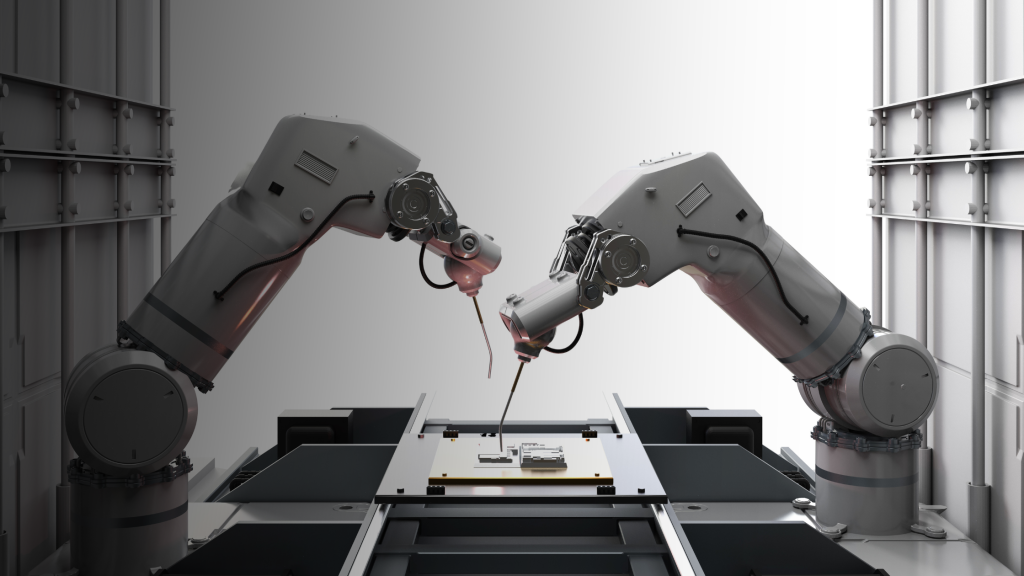

Pick-and-place machines play an important role in both methods. These automated systems accurately position components on the board before soldering, increasing efficiency while minimizing errors.

Re-flow soldering complements SMT by using heat to melt solder paste, creating secure electrical connections with minimal risk of damage to delicate parts. Each technique has its advantages, depending on factors like design complexity and production volume.

Importance of PCB Assembly in Modern Electronics

The role of PCB assembly cannot be discarded in the world of electronics. They sever as a back bone to electronics industry.

Many industries such as consumer electronics and defense use high end electronics assembly to manufacturer electronics. This ensures efficient and quality in the product. With precision assembly technology this can be achieved.

With increase in demand for reliable and efficient electronics in modern world, electronics manufacturers are upgrading their assembly technology to provide high quality and precise assembly services for their customers.

Moreover, with the rise of smart technologies and IoT devices, precise PCB circuit board assembly becomes essential. These applications often require intricate designs and compact layouts that can accommodate various functionalities within limited space constraints.

Cost efficiency is another vital factor linked to effective PCB board assembly practices. Streamlined processes reduce production costs while maintaining quality standards. Manufacturers who invest in advanced techniques benefit from reduced waste and improved turnaround times.

In conclusion, PCB assembly is a vital process in the production of modern electronics. It involves designing, manufacturing, and assembling printed circuit boards using techniques like through-hole technology and surface mount technology. Efficient PCB assembly ensures functionality, reliability, and cost efficiency

Look for PCB assembly service?

At tecno systems India we provide high end PCB assembly services. Get a quote today.

Contact us!